Elite -- For Promo Products, Distributors, Contractors, Apparel Brands, and Fulfillment Shops

EmbTrak Elite supports all Decorators with 10 or more employees, including Promotional Products, Distributors, Contractors and Fulfillment shops. It can work as a standalone system, together with QuickBooks, for sales orders and production. It also complements existing systems by adding unique world class decoration features. It interfaces to import orders from any ERP system, from SAP to Dynamics to SAGE. It also works with SFA's like RepSpark and VRLink, as well as web stores and Ship Station.

It is our goal to help decorators turn out the lowest cost, highest quality products with the shortest turn time in the industry.

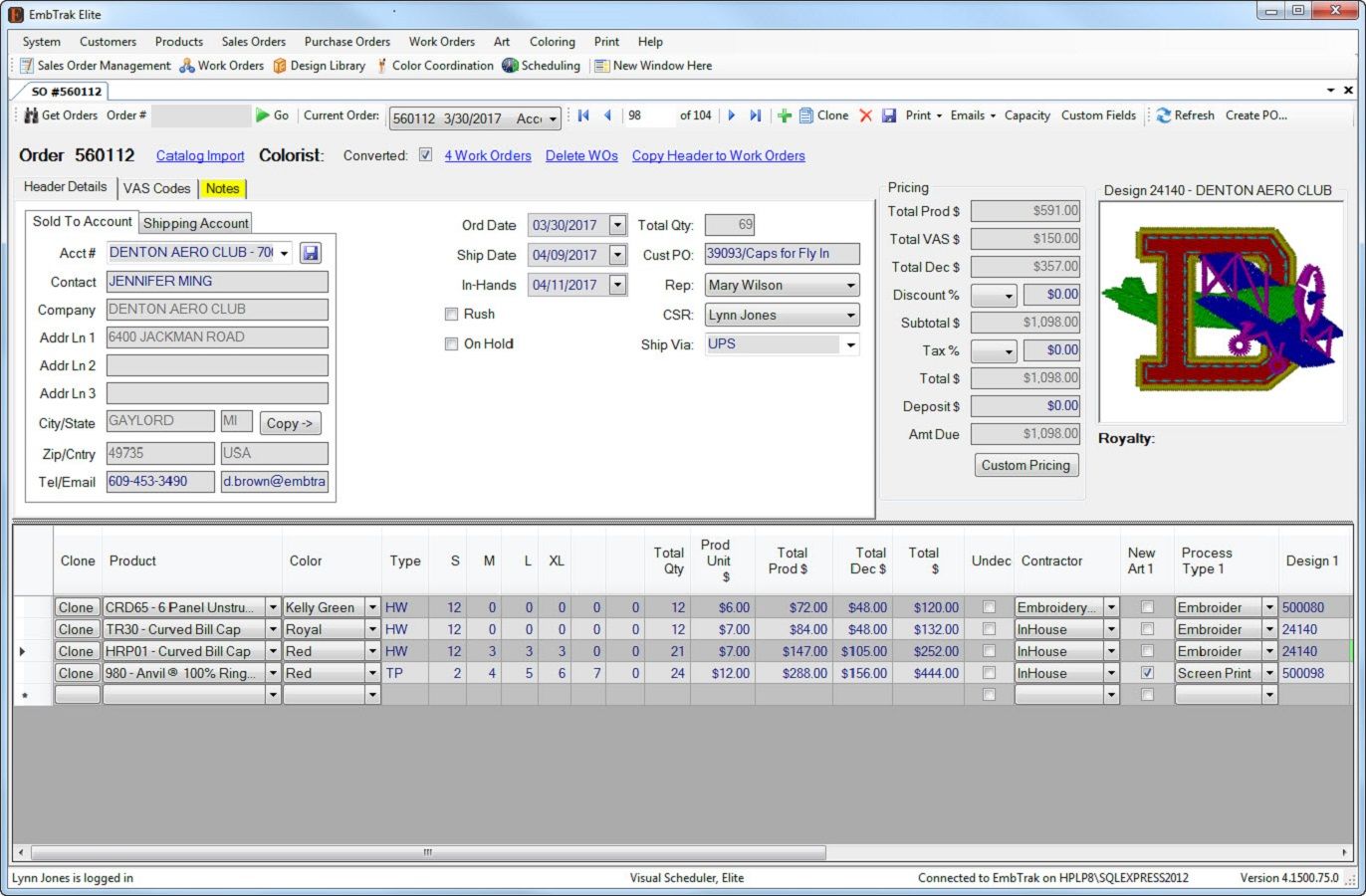

Sales Order Entry

Enter new orders from scratch, or validate orders imported from an ERP system. Everything needed is here: PromoStandards connections to your suppliers so you can see products, colors, prices, and stock availability and import selections into your order. Multiple sizes per line, Value Added Services, pricing, add customers and designs on the fly, designs, positions and personalization. Select from multiple colorways and see sales color history by design and product. There is even a capacity tool to view stitch counts of WIP goods in production by date so you can correctly set promise dates. Best of all, enter .AI, .PDF, .DST or UO1 stitch fles and see the file themselves--not pasted JPG copies like other "decorator" systems. By combining the actual files you will use in production with the actual orders, you ensure quality and save labor.

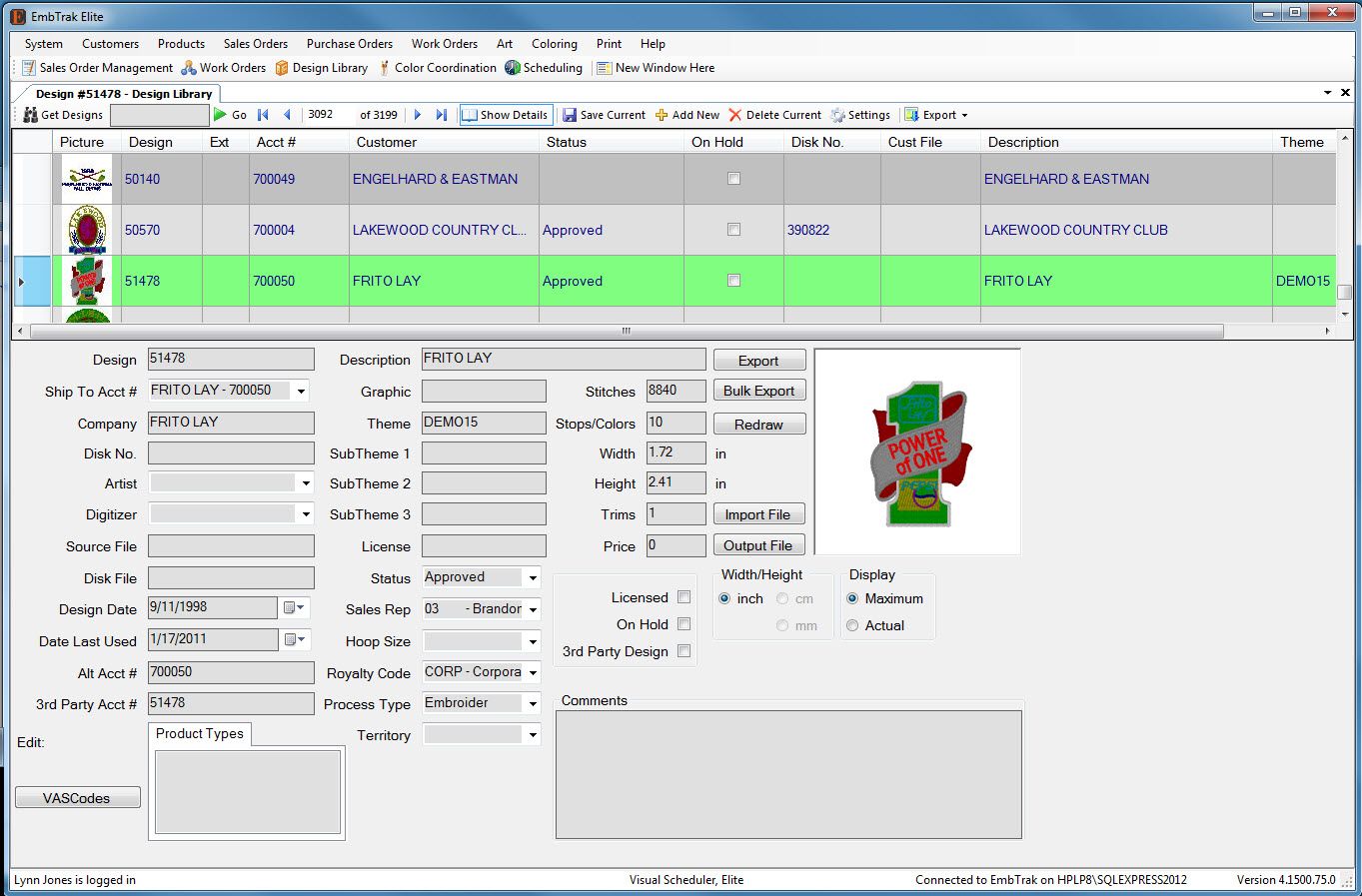

Design Library -- Maintain a "Design File of Record"

The Design Library makes it easy to manage the official, authoritative copy of your art files in one place. This "Design File of Record" shows and prints automatically in EmbTrak on every order where it is referenced. Search by customer name, account number or 20+ other fields. Every user can be authorized to add/edit/view or update art files including stitch files like .DST, .UO1 and .XXX--It eliminates the need to spend more than $900 per user on a popular art file manager product.

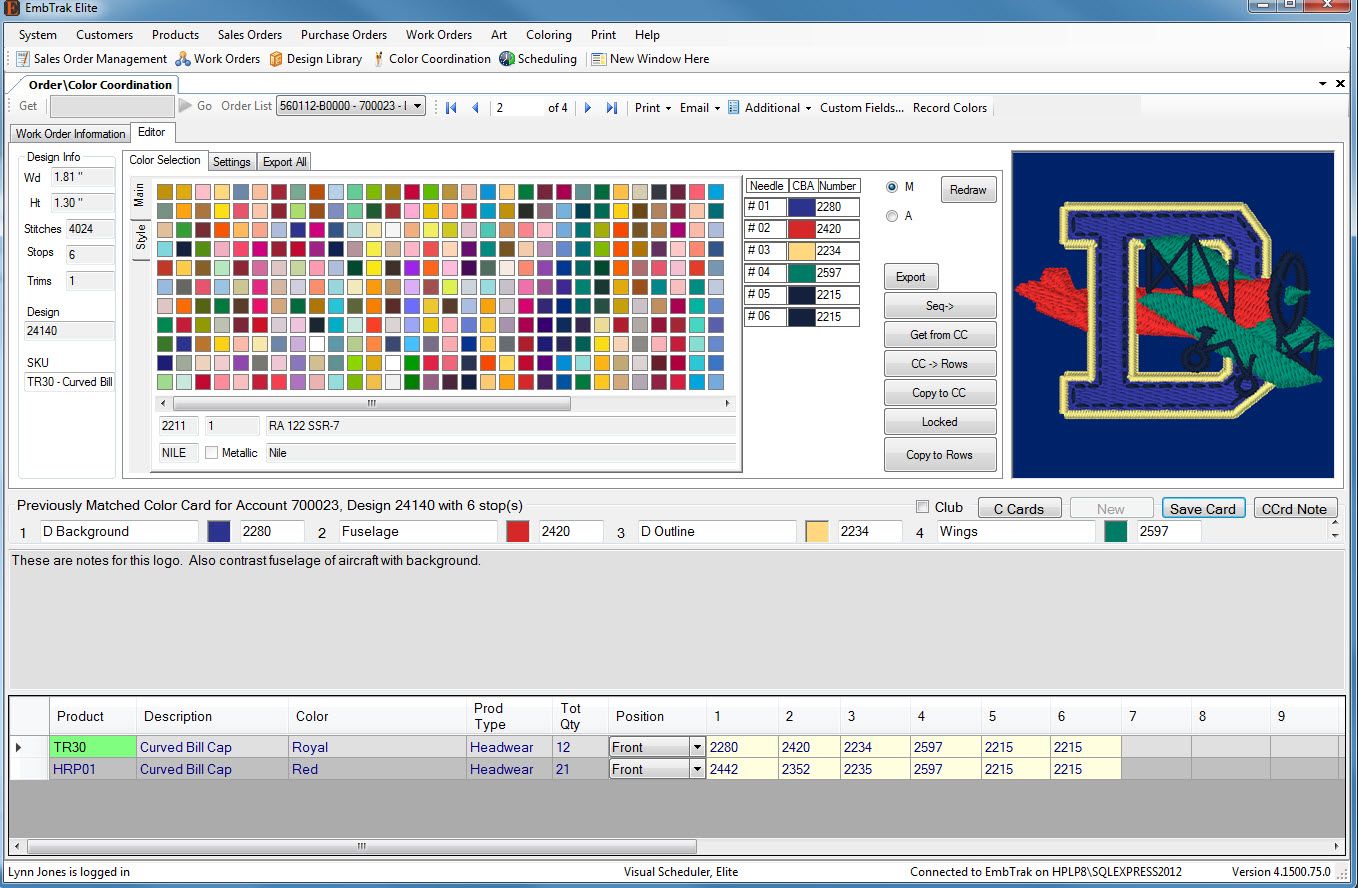

Color and Set Up a Decorated Order

This is the heart of the EmbTrak system. It was first developed in 1999 to help Slazenger Golf quickly color golf logo orders. Today, it is even better. For screen printer orders it has .AI and .PDF views. For embroiderers, it gives a realistic 3D view of a selected stitch file, which instantly updates with the selected threads from manufacturer palettes. Recall colors used on the last order for this logo and account. Pull up the standard color card for this design. Export 3D proof pages for an entire sales order in 10 seconds. With this tool, users can set up an order in less than a minute, instead of 10 or more..

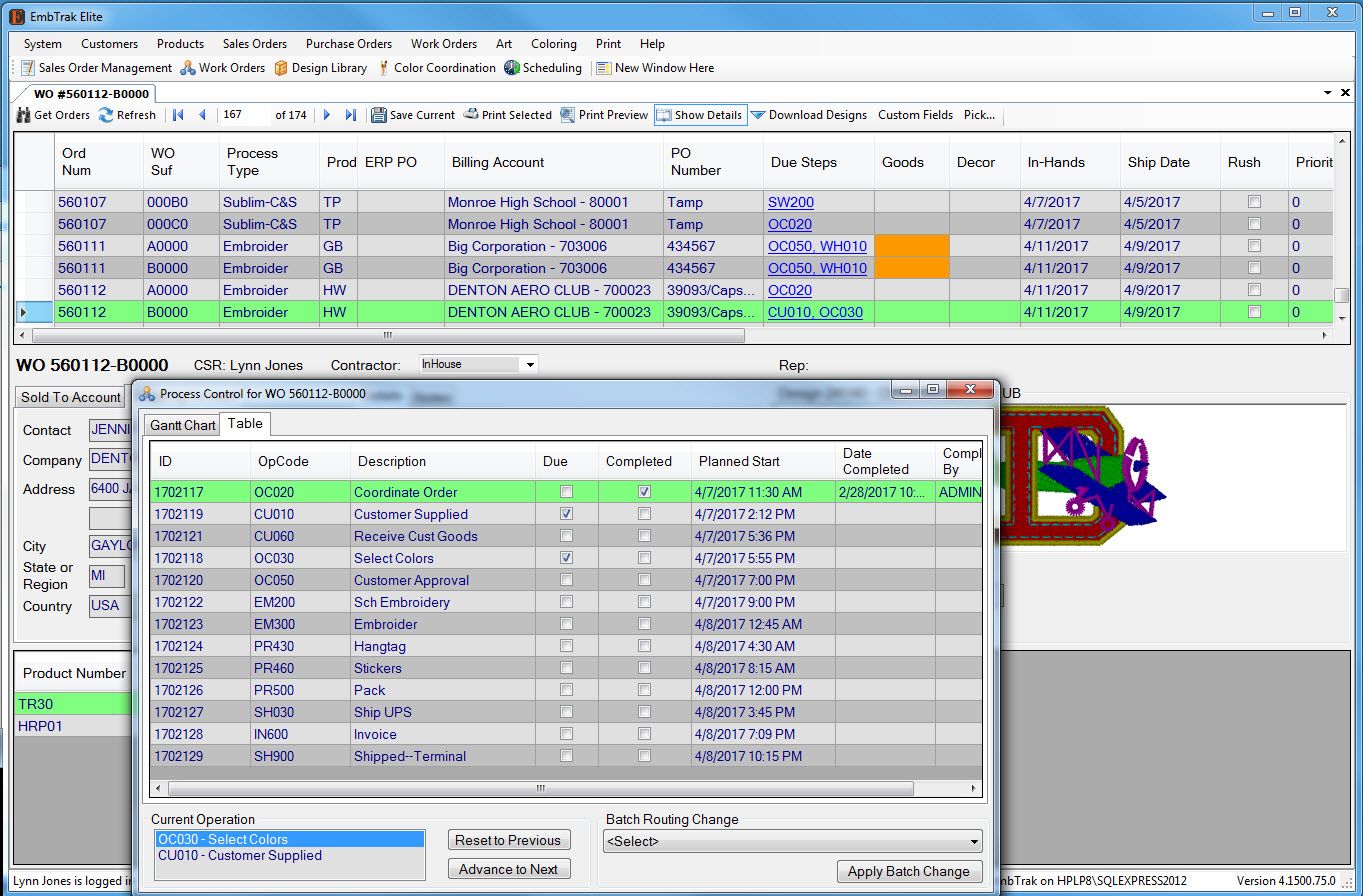

Control the Flow of Orders

This screen gives the user the power to find any order or group of orders in the system instantly and sort them by any column header. Based on our dynamic workflow process, each order moves through a completely configurable set of operations based on the characteristics of the order--not four or twelve fixed steps like other systems. With this approach, missed operations and missed ship dates never need to happen again.

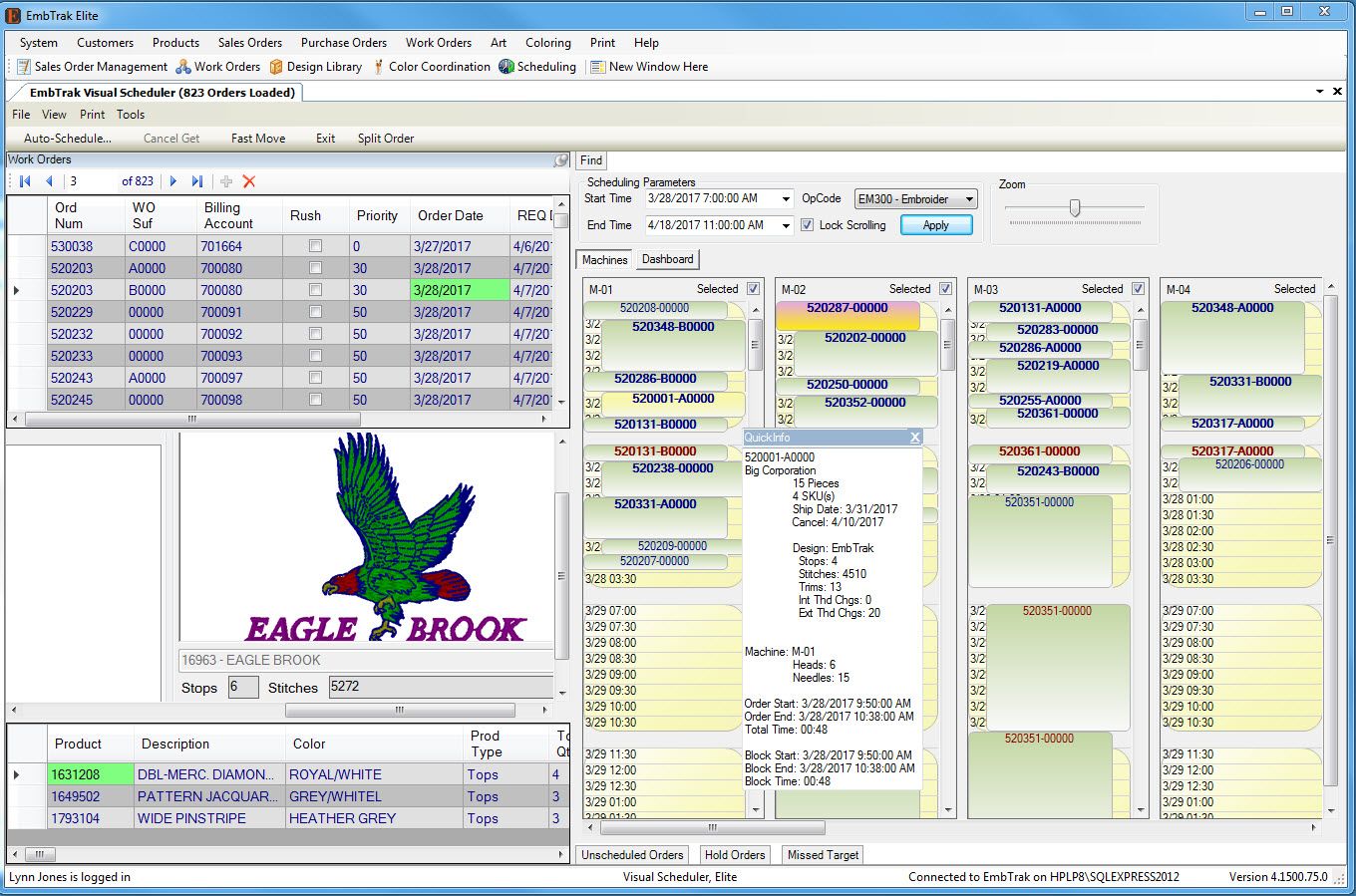

Visual Scheduling

This scheduler does not use rough estimates for the run time on a job, like other systems. With a Visual Scheduler screen for Screen Print and one for Embroidery, the schedule for each is done by process specific calculations. It uses factors such as embroidery file machine trims and stops and screen print image height and width. Machine characteristics such as stitch speed and number of needles and palette size are considered. And much more. In short, Visual Scheduler schedules thoroughly, correctly and quickly. This frees your production manager to manage rather than crunch numbers. It not only schedules, it can automatically optimize where and when orders are run for maximum efficiency. An in-depth study at a large shop showed an increase in capacity of over 18% versus their in-house schedule system.

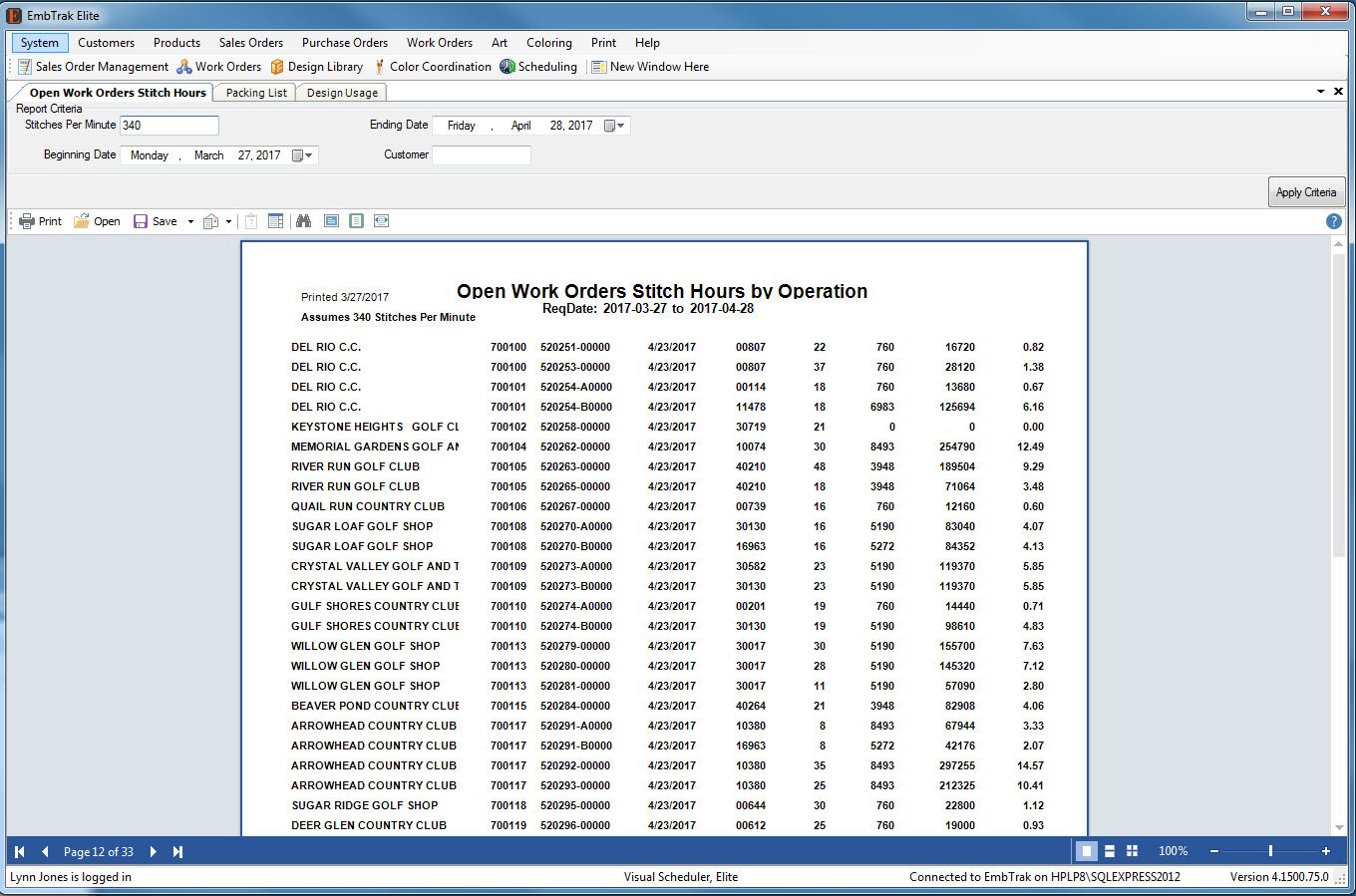

Reporting

EmbTrak has data captured by no other system on the market.--such as actual machine run times for a screen print order or stitch counts read directly from the latest .DST files in the Design Library. We leverage this data to provide powerful reporting to inform management. In addition to a growing list of standard reports, we can also develop specific reports to meet your requirements.

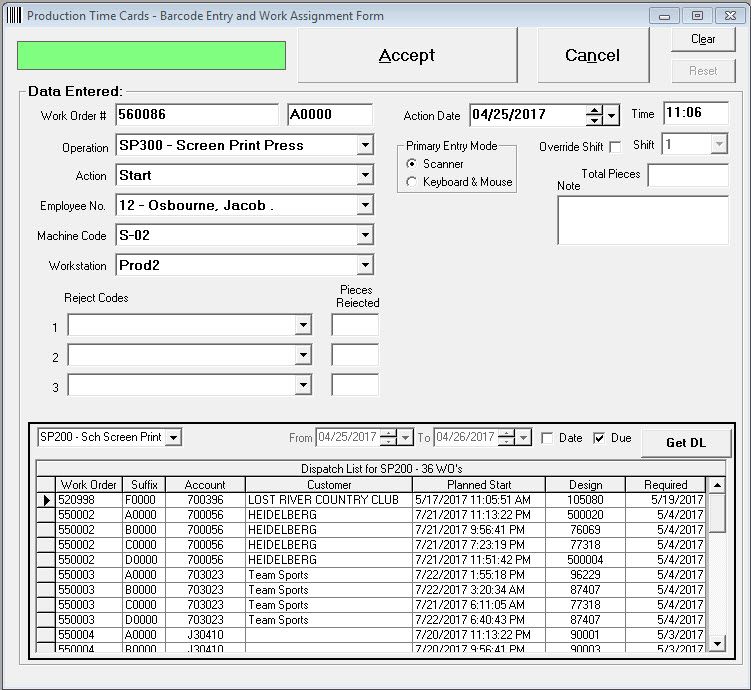

Bar Code Shop Floor Control

The Bar Code system provides accountability and tracking on the shop floor. Any production step in our configurable workflow can be set up to scan. This system has been proven in one of the largest screen print shops in the U.S., where it tracked orders from issuance of pick tickets, through screen printing and various value added services to final shipping. All scanned data is saved to the EmbTrak MS SQL Server database where it can be combined with other information for visibility and reporting.