"Why Do we need EmbTrak? We have a leading Decoration system."

In short, you need EmbTrak because it provides critical PRODUCTION tools the designers of other systems never considered.

Decorator systems first sold in the nineties were the first generation of software for the small shop. They simply converted manual tasks to the computer. They sped up tasks like creating and printing orders so they were an improvement over paper. They had fields for designs, positions and processes so they could claim to be “decoration” programs. But, they did almost nothing to improve quality or leverage the real power of the computer.

Through the years, these small shop systems have remained essentially unchanged.

EmbTrak is different because it began in response to the needs of large apparel companies. Our first client was Slazenger Golf. In short we improved productivity in the preparation area so that ONE person did the work of FOUR. We also improved quality so that customer Returns dropped from 2% of Net Sales to virtually zero.

Next we wrote a program to optimize the scheduling of embroidery and later added scheduling of screen printing.24 YEARS LATER, NEITHER THE COLORING TOOL NOR THE SCHEDULING TOOL ARE MATCHED BY ANY OTHER SOFTWARE.

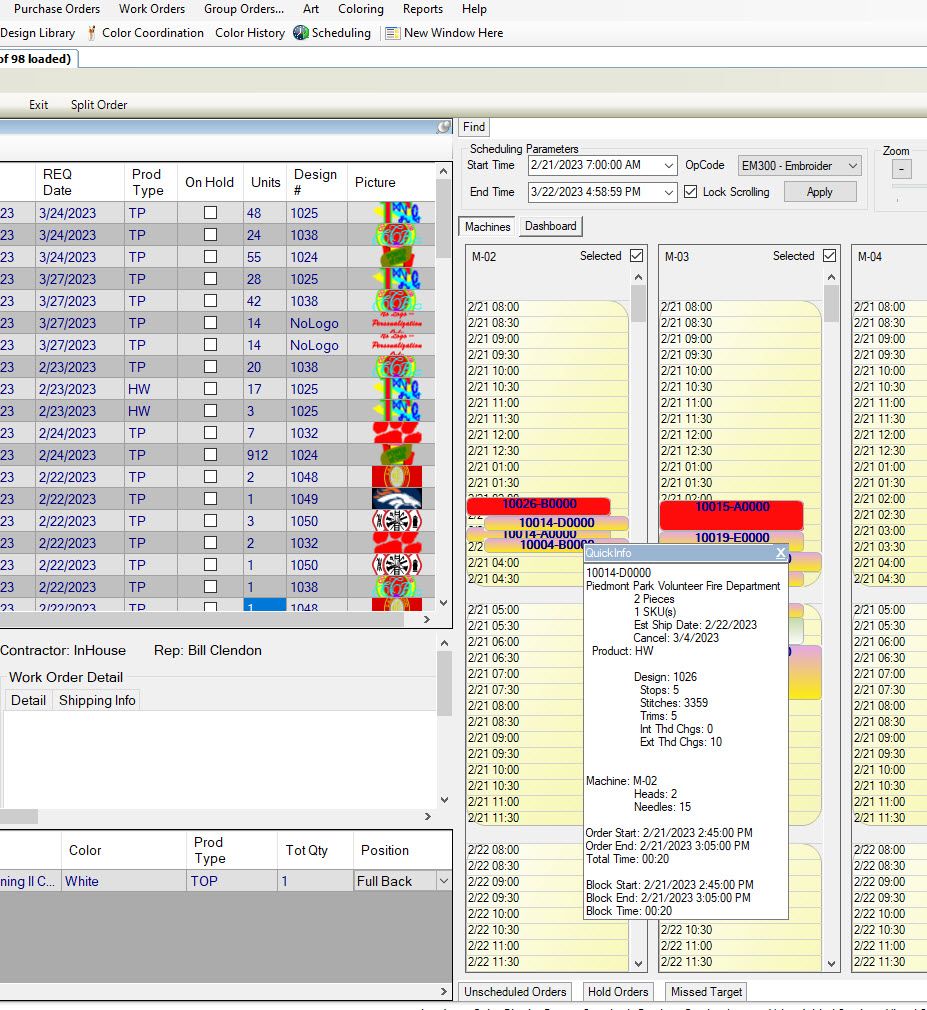

We built real schedulers for Screen Print and Embroidery

More about scheduling. There are systems on the market that claim to schedule. All they really do is allow the user to put orders on a time space to run on a given day with rough calculations to estimate runtime.

It is true that both the EmbTrak Screen Printing and Embroidery Schedulers look virtually identical. And to look at them, one might think they are the same as the simplistic schedulers in other software.

But, what we call scheduling is on a par with state-of-the-art scheduling in advanced manufacturing. For example, for both screen print and embroidery we first let the user pick the machines to schedule, chose orders to run and start the scheduler. The rest is automatic, although the user always has the option to drag and drop orders where they prefer.

The difference is in the calculations and factors used in each. EmbTrak defines machines and orders by their characteristics such as stitch speed, or palette size, current inks, flash times and many more. We use Industrial Engineering (IE) rates to determine how many manhours for actions to complete the order. We determine the best machine for a given order to run on. Algorithms solve for an optimum solution. Drags and drops let the user modify as needed. In short, we do it the way it should be done.

Complicated? Yes, the background calculations are too much for a human. But the scheduler is dead simple for anyone to run.

A computer does each order in milliseconds. It not only optimizes machines, it gives a manager hours a day for more important work a computer cannot do.

Does it work? Exceedingly well. One of our major prospects had two Process Engineers evaluate EmbTrak against their proprietary scheduler for one month.

THEY FOUND THE SCHEDULES DONE BY EMBTRAK IMPROVED THROUGHPUT BY 18.3% PER SHIFT WITH NO INCREASE IN LABOR OR MACHINE COST. And this was compared to their own computer scheduling.

They bought EmbTrak.

We continue to improve the Overall Production process

Since 2000, EmbTrak has been in constant development to help you. Users can now:

1) On Machine Scheduling a. Match screen printing image area to the palette sizes currently installed on machines. b. Calculate ink changeover time from current jobs to prospective orders.

c. Automatically pull multiple matching onesy-twosy orders into larger SUPER-ORDERS to run on embroidery multi-head machines.

d. Automatically optimize the tradeoff point for each machine for its number of heads, between head utilization percentage and job runtime.

2) With Art

a. Automatically color imported orders. At one shop this reduced the coloring team from eleven to three full time staff.

b. Select colorways from design and account specific drop lists on the Sales Order screen. This is a big benefit for distributors.

c. Keep SKU, color and quantity of every item on every sales order decoration which used a Color Card. This is a key to improving turn time and accuracy.

We added Barcode Scanning

A barcode scanning system is an essential tool for controlling the Shop Floor. Barcode scanning in EmbTrak supports three critical functions. First, it can quickly scan every work order at every operation. Since scans are updated to the EmbTrak database instantly, any operator can locate any order in the shop instantly. Second, the routing system automatically plans a path for each order through every required operation. The scanning system will not permit a change to that sequence without a supervisor override. Third, EmbTrak can generate reports which compare the planned time for operators to do embroidery or screen print orders. This provides the most accurate performance measure in the industry for decoration staff.

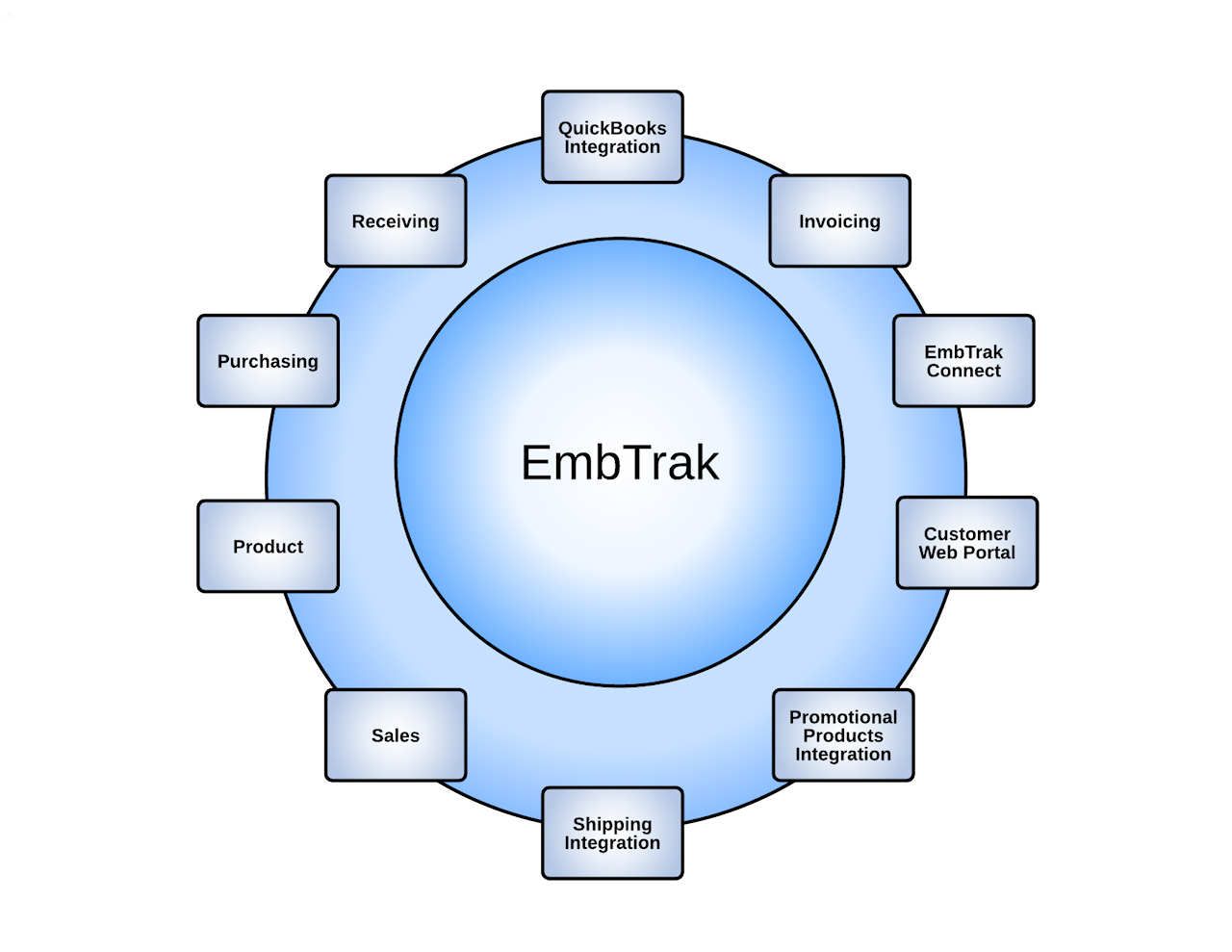

We Added the Business Functions you need

While keeping our focus on industry leading decoration features, we know that Decorators of all types also need business functionality.

So, we integrated with ERPs, shipping software and QuickBooks. We added EmbTrak Connect (see below). We added a fully configurable multi-parallel path routing system, added Purchase Orders, created a Customer Portal, added a Promotional Products interface, and ensured that every major business requirement for small and medium sized shops is present.

We have also defined the decoration industry's "Best Practices" and incorporated these into EmbTrak.

We Built the DecLINK Network

We built a full-featured network for connecting Distributors to their Production/Fulfillment Contractors. It is called DecorLINK .

This system will cut the time to transmit and gain acceptance of an order by the Contractor from hours or days to minutes.

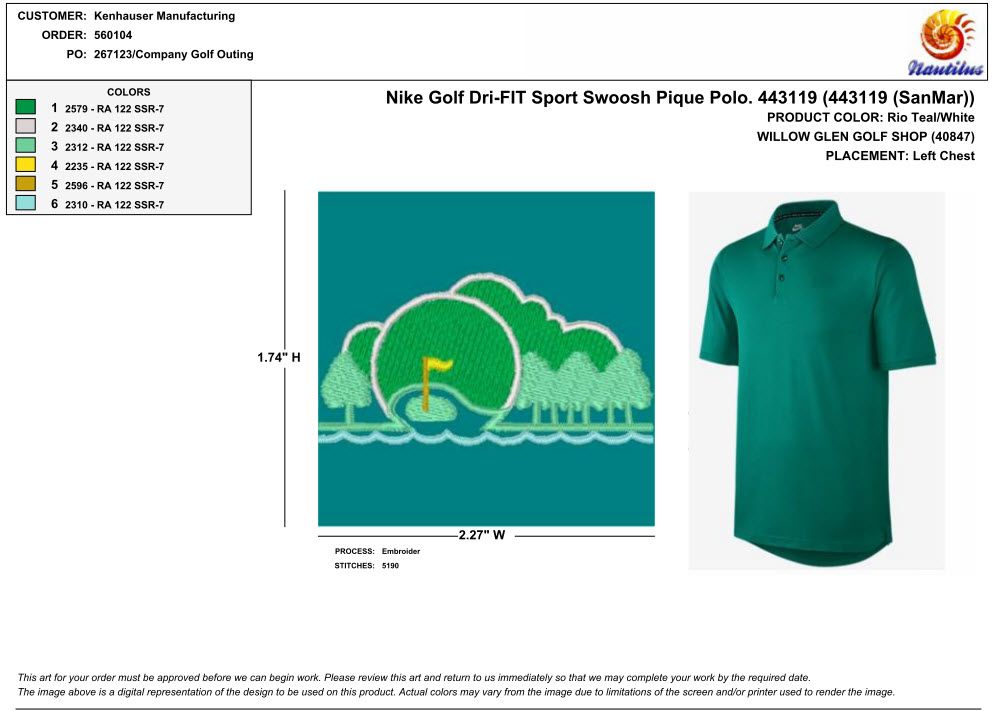

We Added Computer Generated Proofs

It has become, as one of our clients puts it, “the Gold Standard for customer proofs”.

We Support Continuous Process Improvement

CONTINUOUS PROCESS IMPROVEMENT WILL BE THE GAME CHANGER FOR DECORATION SHOPS OVER THE NEXT FIVE YEARS. Owners who implement will thrive. Others will not.

EmbTrak does not just allow CPI, it has built in support for recording and reporting CPI results.

Our Objective: Perfect Logos. Extreme Profit. Contract Now. Ship Today.

That tagline summarizes the ways in which your shop can benefit from an EmbTrak implementation. In the end, it all comes down to Quality, Service and Price. As long as the status quo is unchanged, you cannot improve all three factors at once. However, EmbTrak and Continuous Process Improvement are each and together, game-changers. It's not free. It will take your time and effort. But it is the best thing you will ever do for your shop. Call EmbTrak today at 864-483-8586 OR email d.brown@embtrak.com to find out more.