"Why Do we need EmbTrak? We have a leading Decorator system."

Decorator systems first sold in the nineties were the first generation of software for the small shop. They simply converted manual tasks to the computer. They sped up tasks like creating and printing orders so they were an improvement over paper. They had fields for designs, positions and processes so they could claim to be “decoration” programs. But, they did almost nothing to improve quality or leverage the real power of the computer.

Through the years, these small shop systems have remained essentially unchanged.

EmbTrak is different because it began in response to the needs of large apparel companies. Our first client was Slazenger Golf. They showed us the printed work order that fell out of their Enterprise Resource Planning (ERP) system. The coloring team of four picked it up, chose spools of thread and wrote down the thread numbers in pencil on the order form. Production was 20 orders colored per day per team member. Quality returns were 2% of net sales.

We increased output per person from 20 orders per day to 100. Quality returns went to nil. How?

We continue improving the coloring process

Coloring orders was the first process we created in EmbTrak. We did it by importing the order from the ERP and adding DST decoration tools on the same screen. The result? 1) Output per person went to 100+ orders per day, so one could do the work of four. 2) Quality returns dropped to almost zero because the Design on the screen was not a JPG copy the DST. It was the DST file used by production, so it couldn’t be changed without the colorist being aware of the change.

Since then, we have constantly improved. Users can now:

a. Automatically color imported orders. At one shop this reduced the coloring team from eleven to three full time staff. b. Select colorways from design and account specific drop lists on the Sales Order screen. This was a big benefit for distributors. c. Keep SKU, color and quantity of every item on every sales order decoration which used a Color Card. This was a key to improving turn time and accuracy.

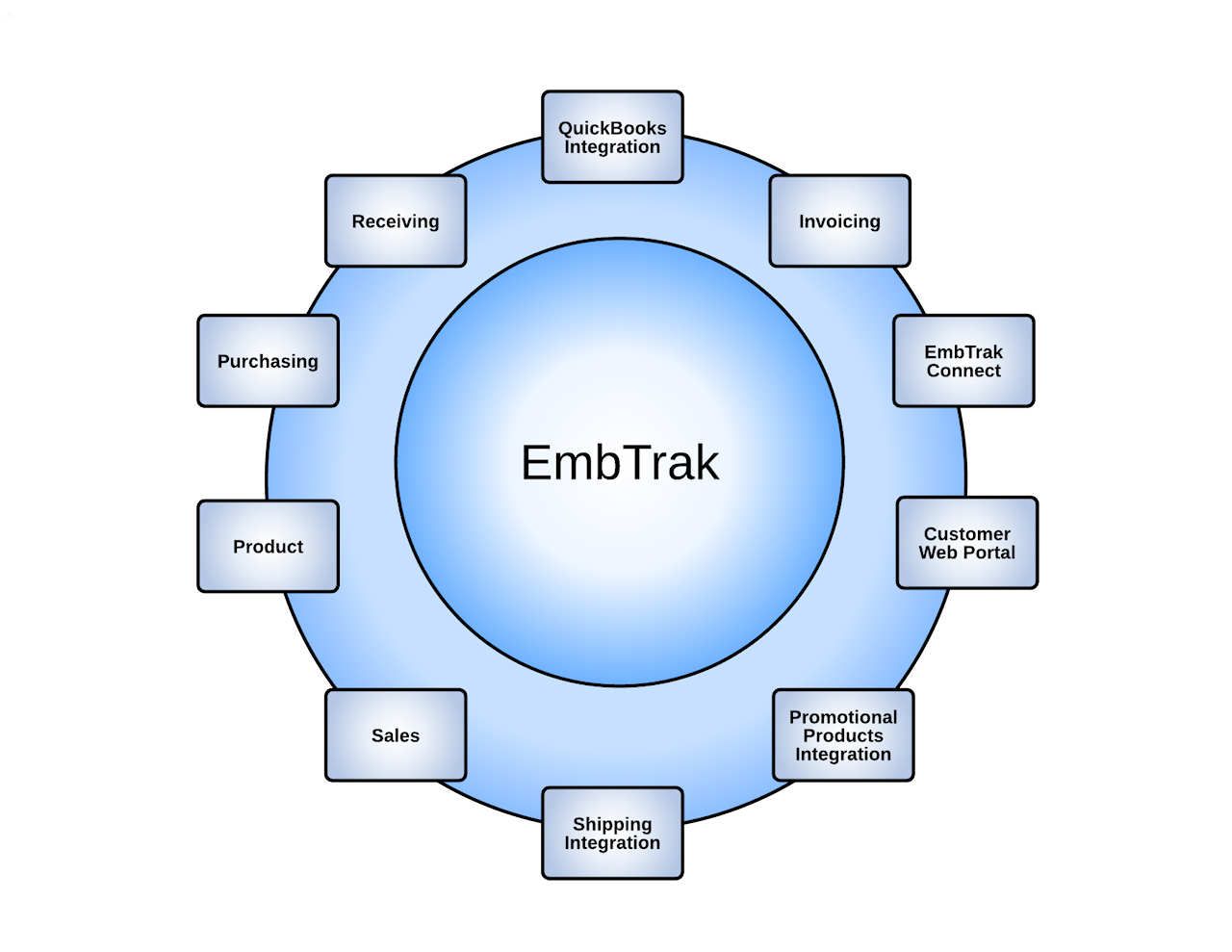

We Added the Business Functions you need

So, we integrated with ERPs, shipping software and QuickBooks. We added a fully configurable multi-parallel path routing system, added Purchase Orders, created a Customer Portal, added a Promotional Products interface, and ensured that every major business requirement for small and medium sized shops is present.

We have also defined the decoration industry's "Best Practices" and incorporated these into EmbTrak.

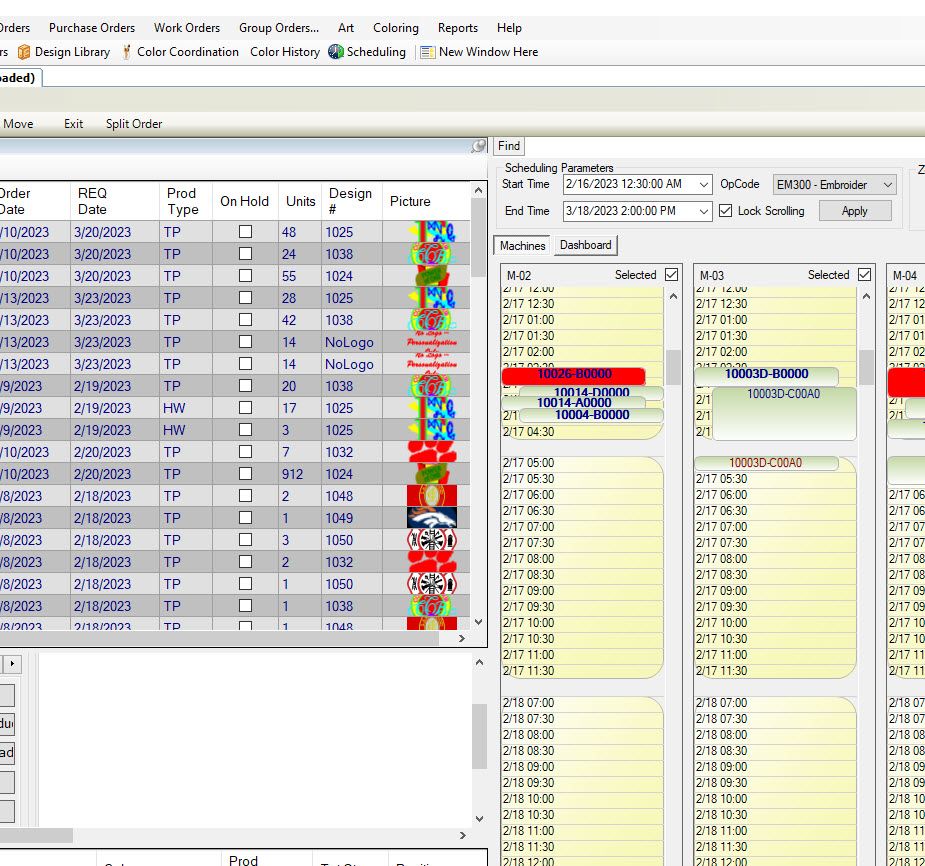

We built real schedulers for Screen Print and Embroidery

First, we added a state-of-the-art scheduling system built around industrial engineering rates. One of our major prospects had two Process Engineers evaluate our scheduling against their proprietary scheduler for one month.

Result? They found that EmbTrak provided 18.3% improved throughput per shift with no increase in labor or machine cost. They bought EmbTrak.

Since then, we have added improvements such as Super-Orders and the ability to optimize the tradeoff point for each machine between head utilization percentage and job runtime.

We Built An Industry Best Network

We introduced the industry’s first network for connecting Distributors to their Production Contractors. It is called DecorLINK .

This system will cut the time to transmit and grant acceptance of an order from hours or days to minutes.

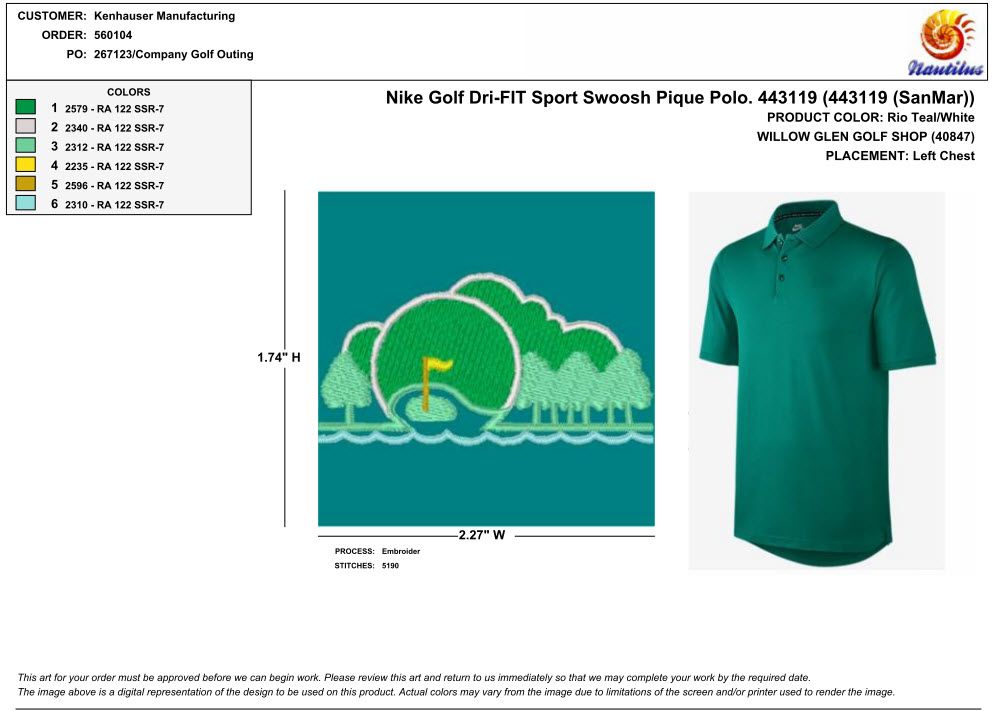

Computer Generated Proofs

Continuous Process Improvement

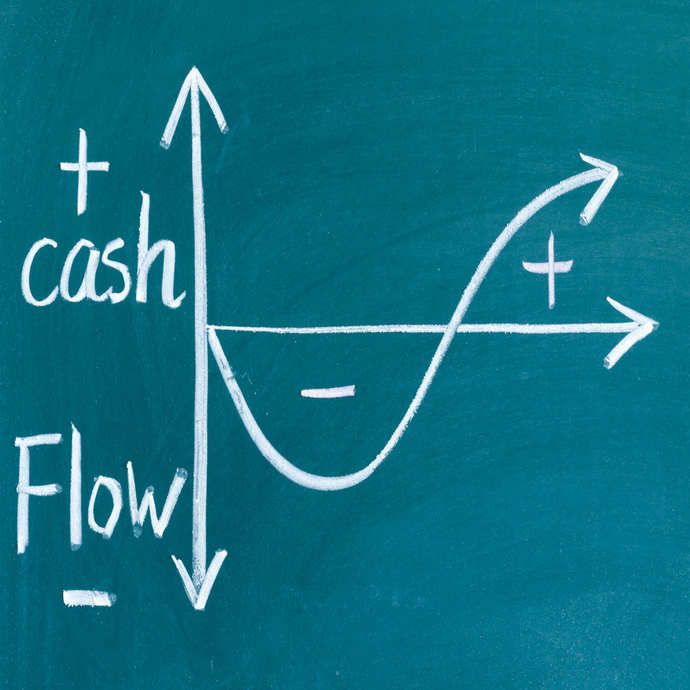

CONTINUOUS PROCESS IMPROVEMENT WILL BE THE GAME CHANGER FOR DECORATION SHOPS OVER THE NEXT FIVE YEARS. Owners who implement will thrive. Others will not.

EmbTrak does not just allow CPI, it has built in support for recording and reporting CPI results.

Perfect Logos. Extreme Profit. Contract Now. Ship Today.

Our tagline summarizes the ways in which your shop can benefit from an EmbTrak implementation. In the end, it all comes down to Quality, Service and Price. As long as the status quo is unchanged, you cannot improve all three factors at once. However, EmbTrak and Continuous Process Improvement are each and together, game-changers. It's not free. It will take your time and effort. But it is the best thing you will ever do for your shop.

Call EmbTrak today at 864-483-8586 OR email d.brown@embtrak.com to find out more.